Ensure a perfect fit for your phone

Precision Crafted

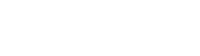

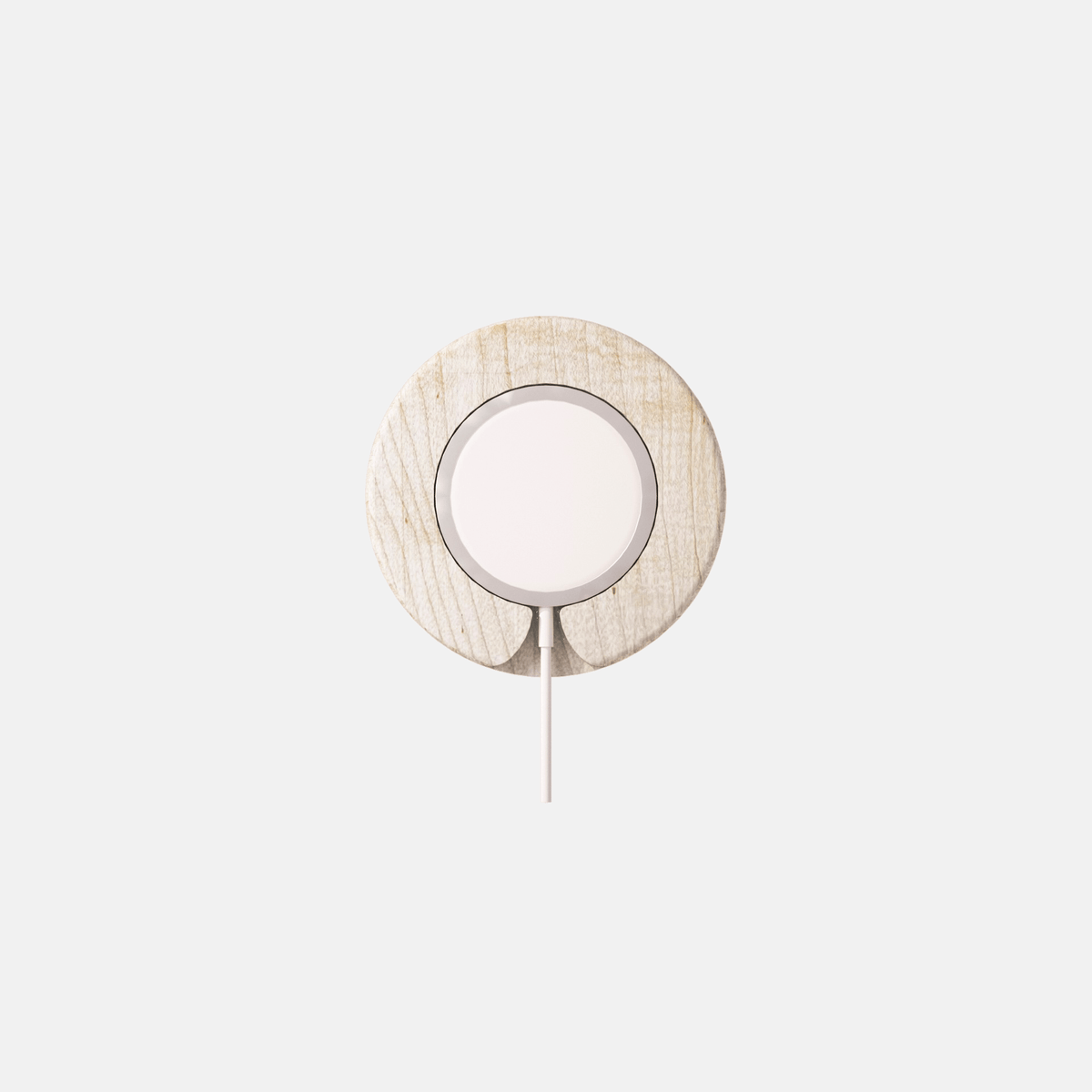

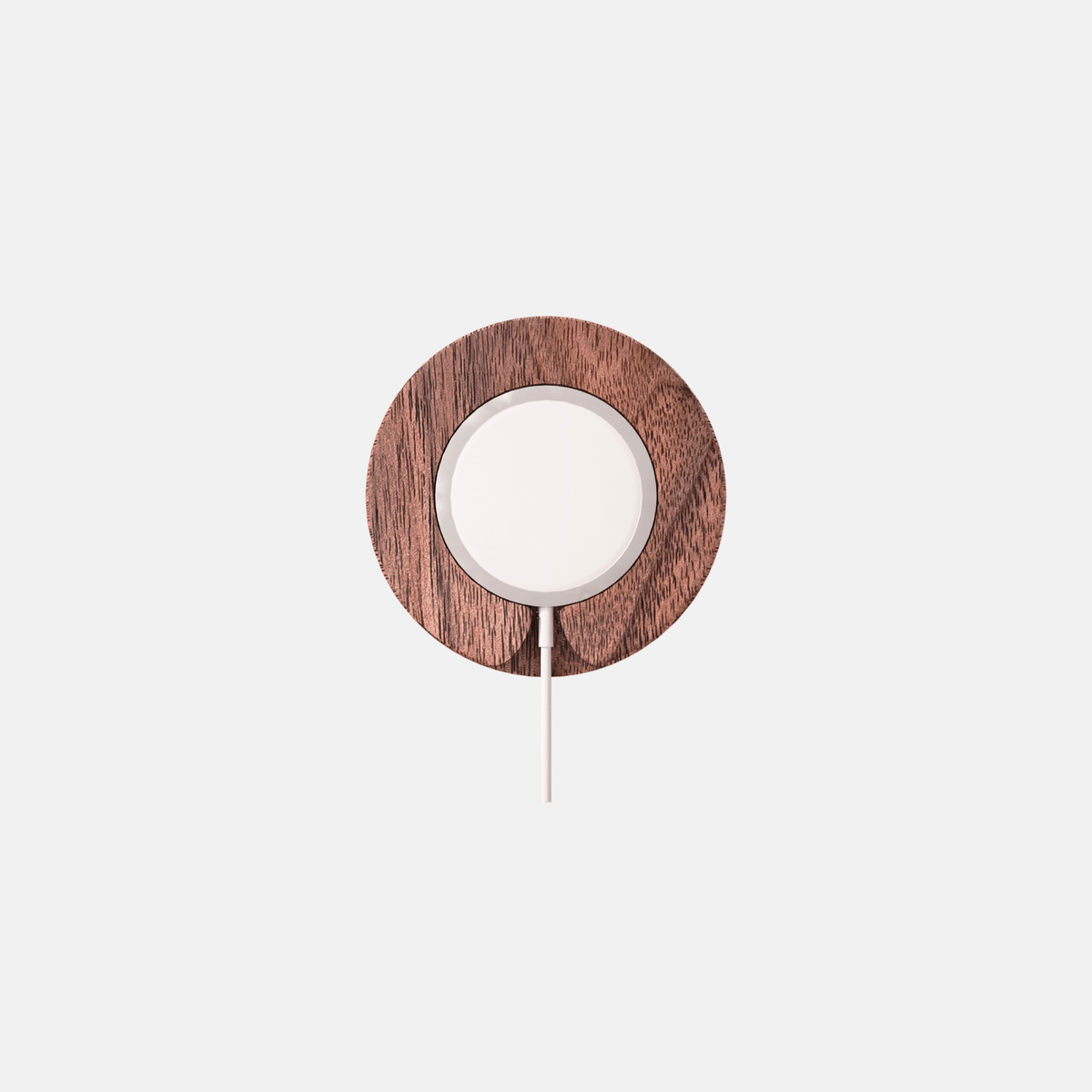

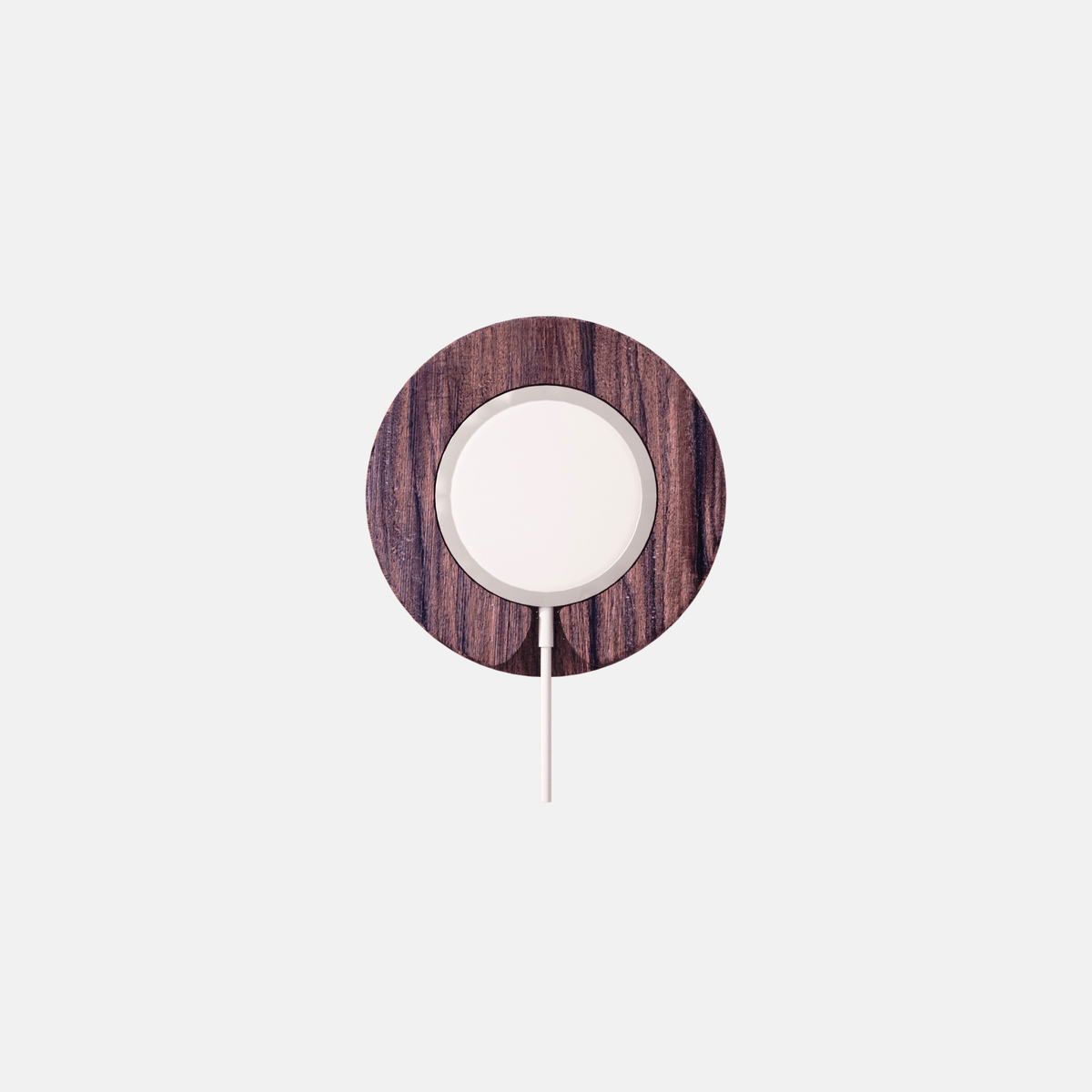

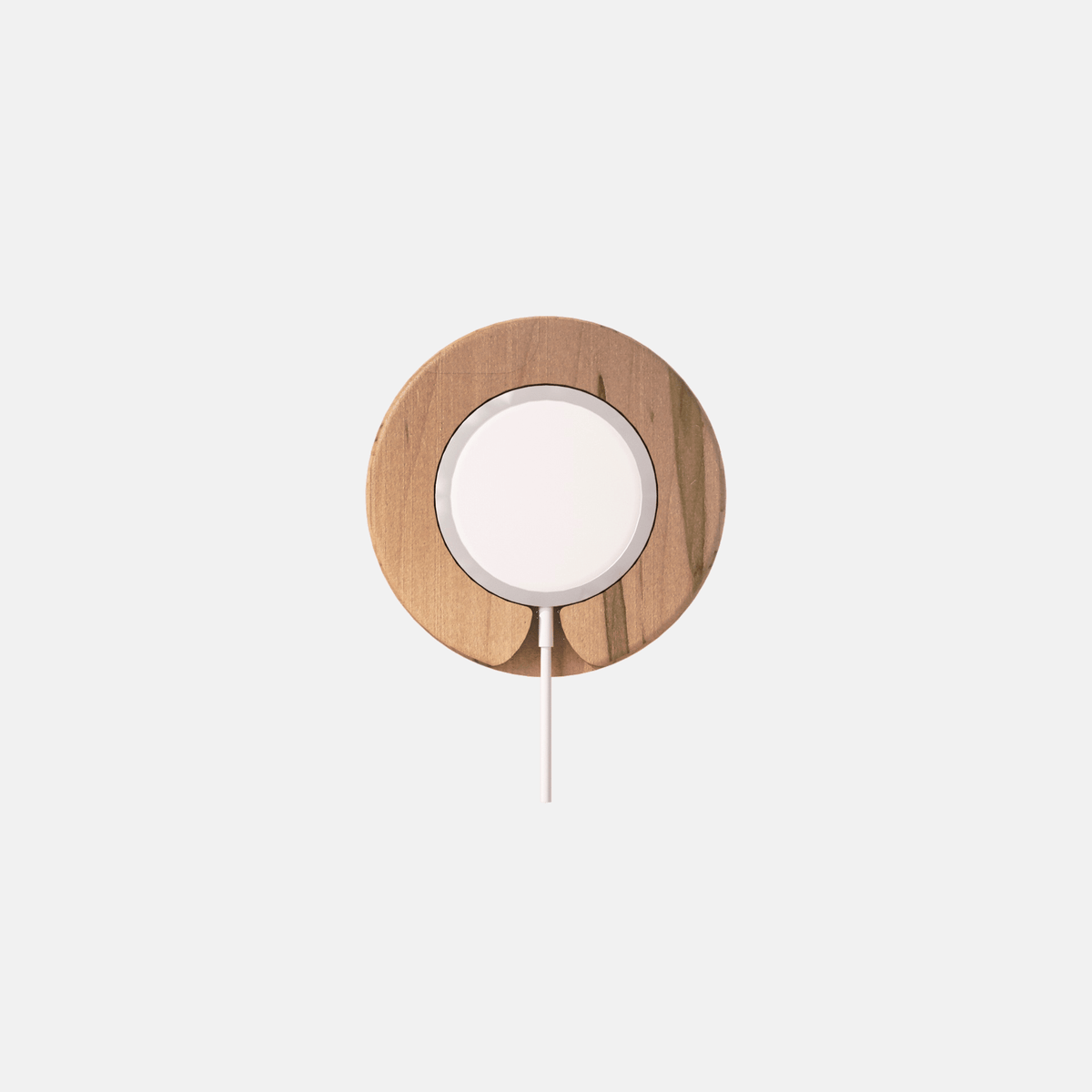

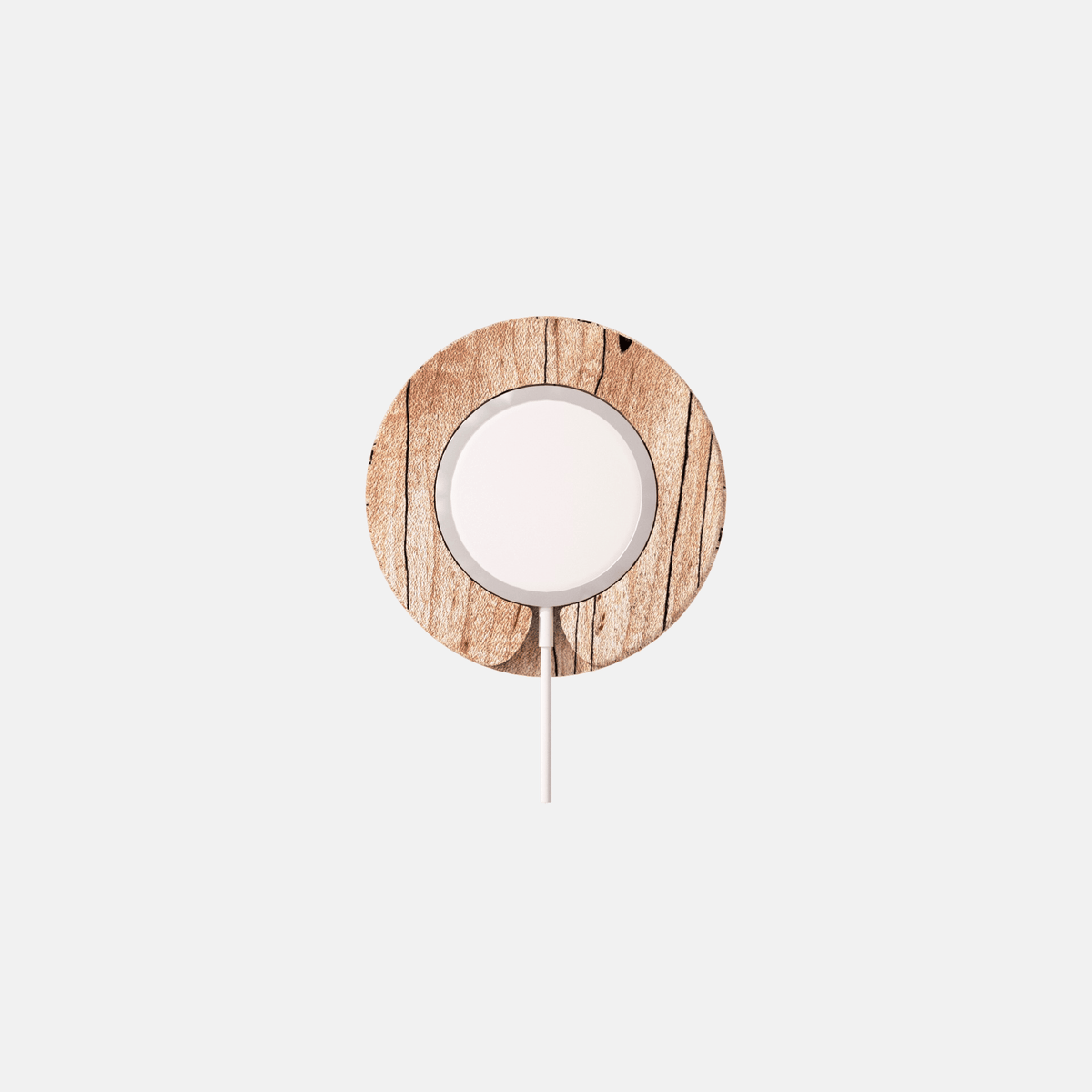

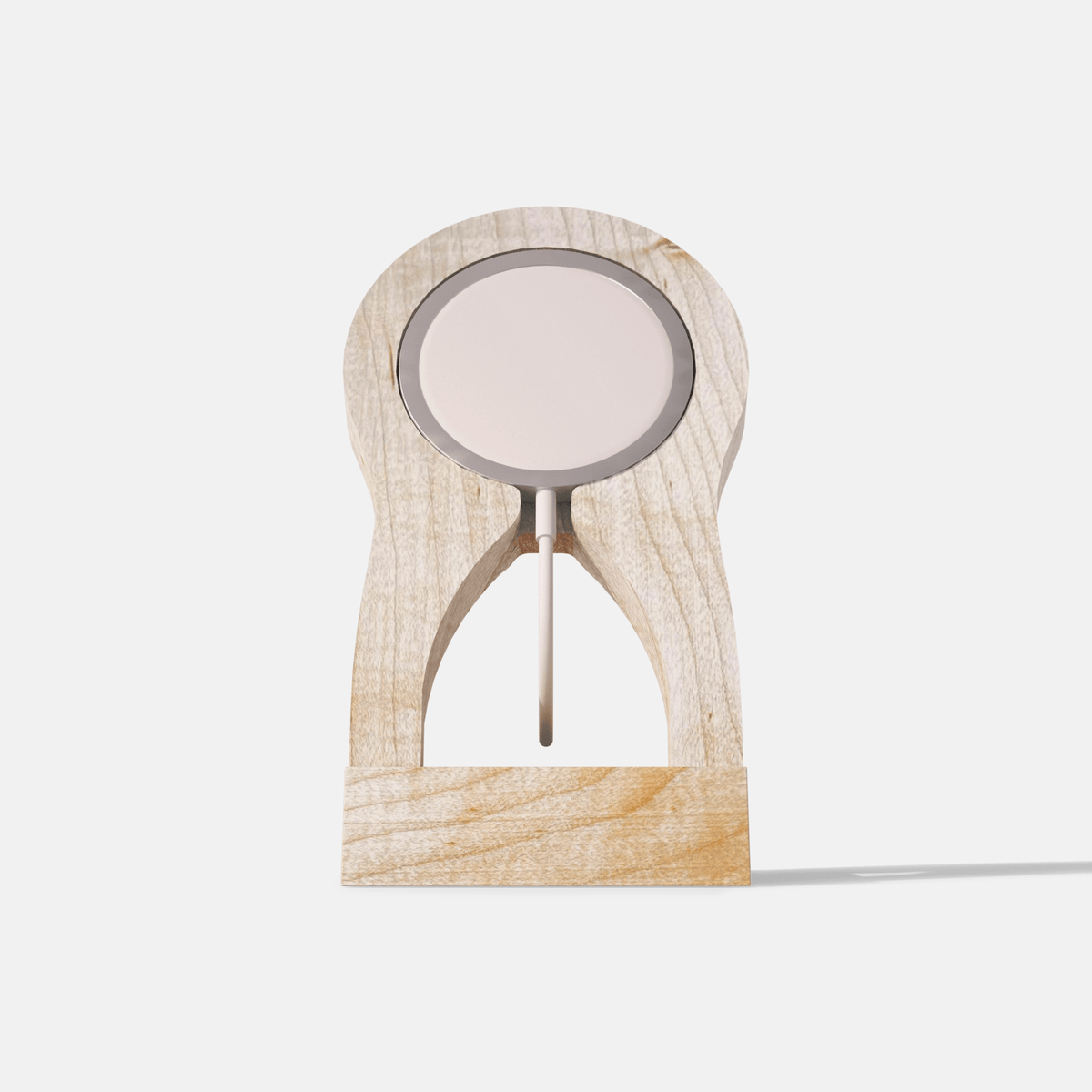

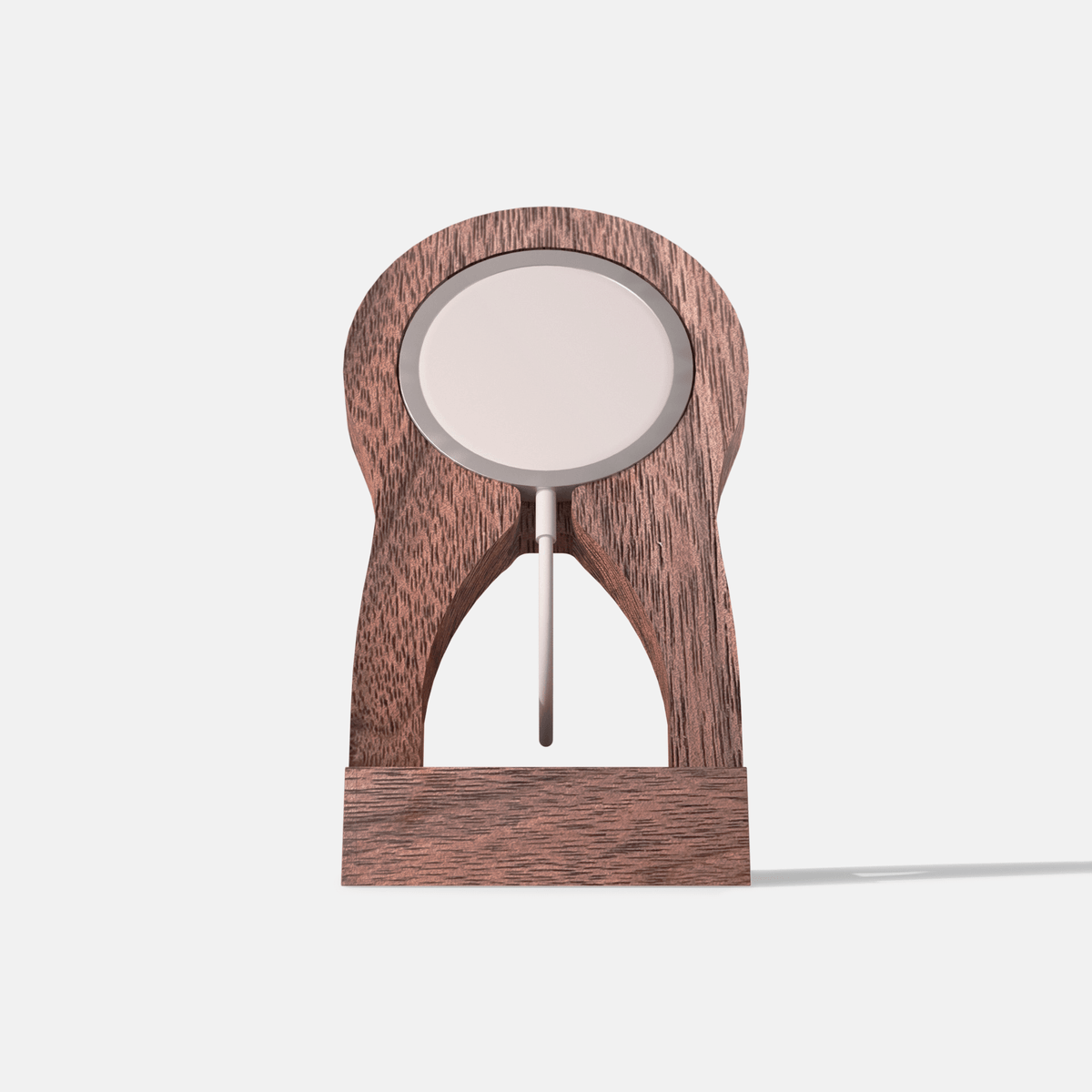

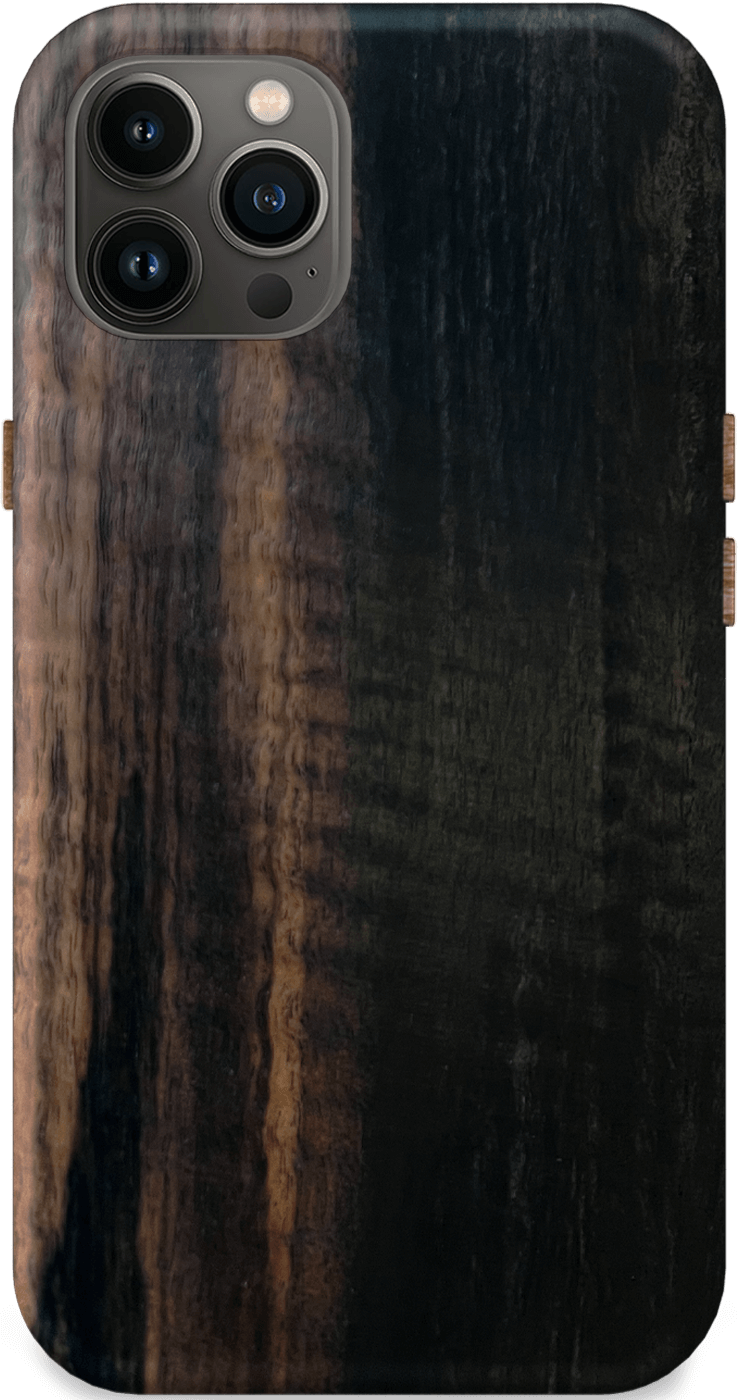

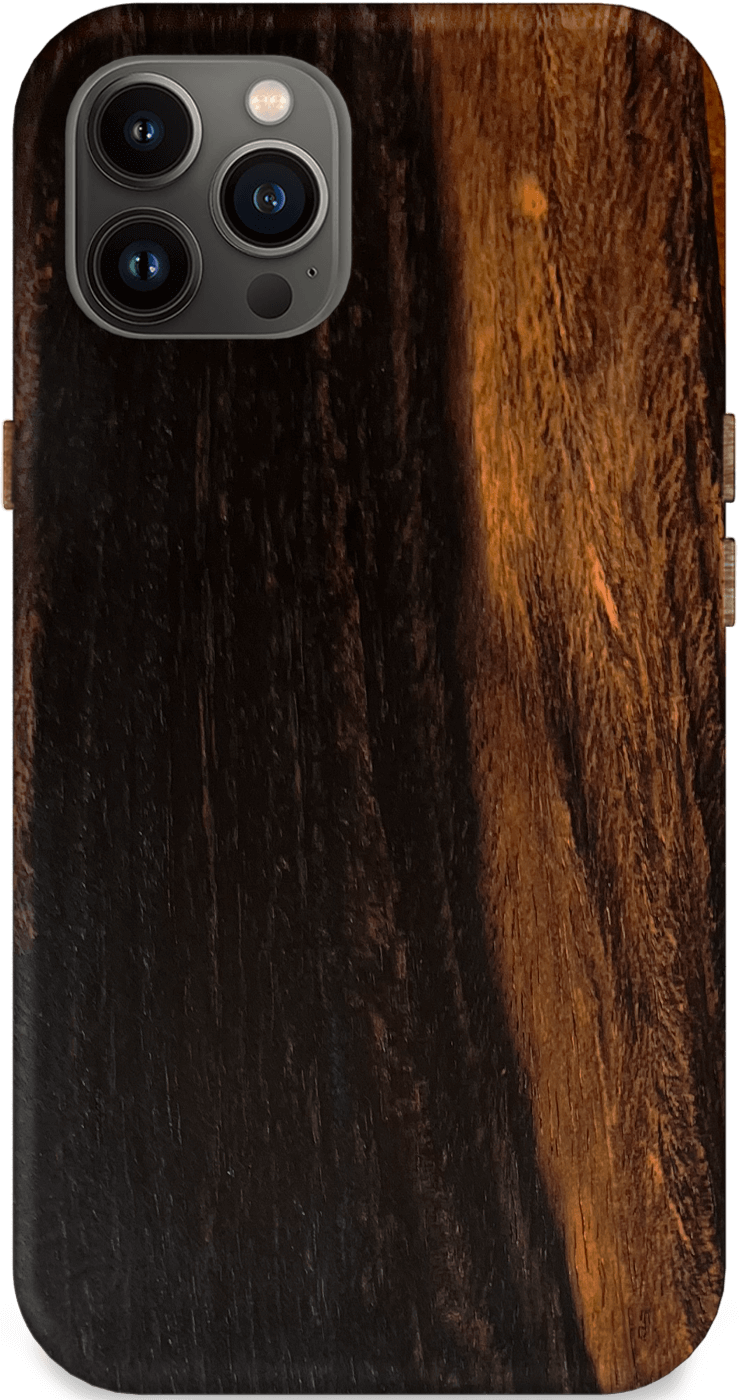

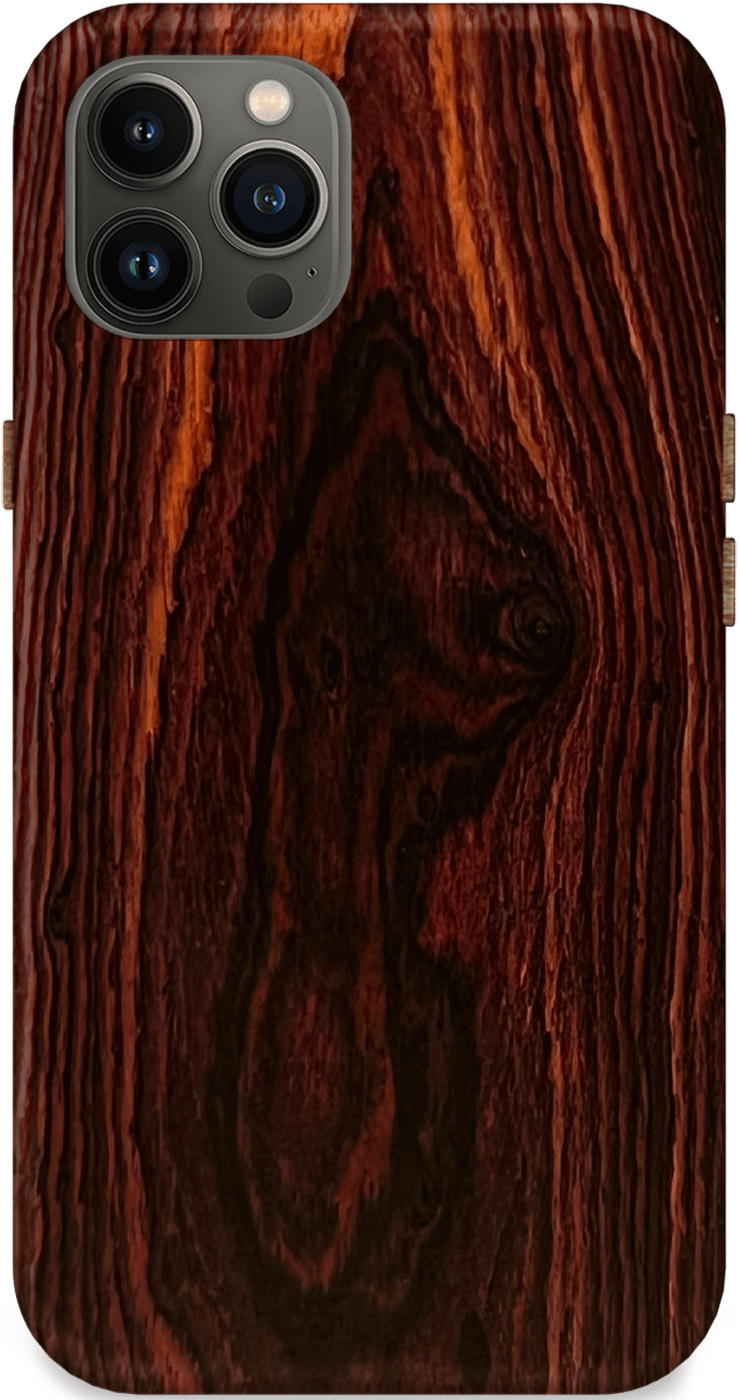

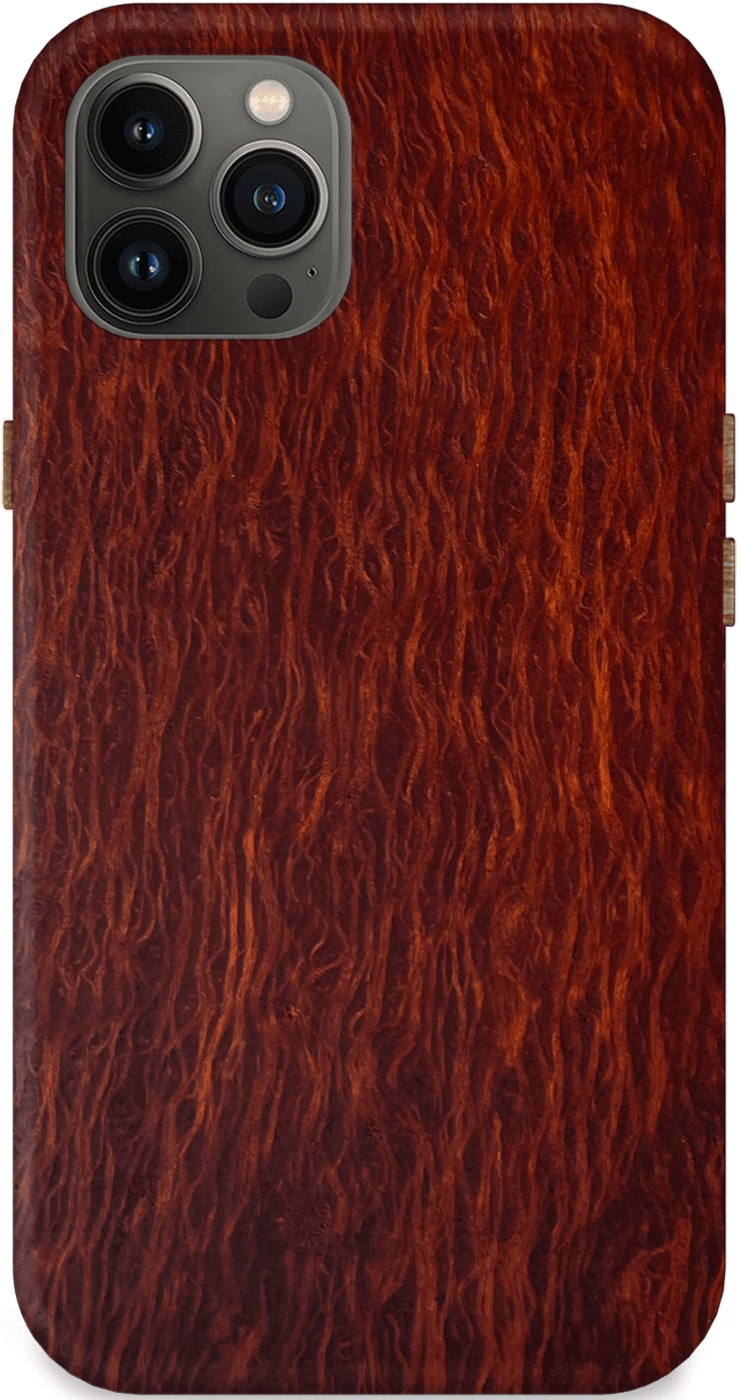

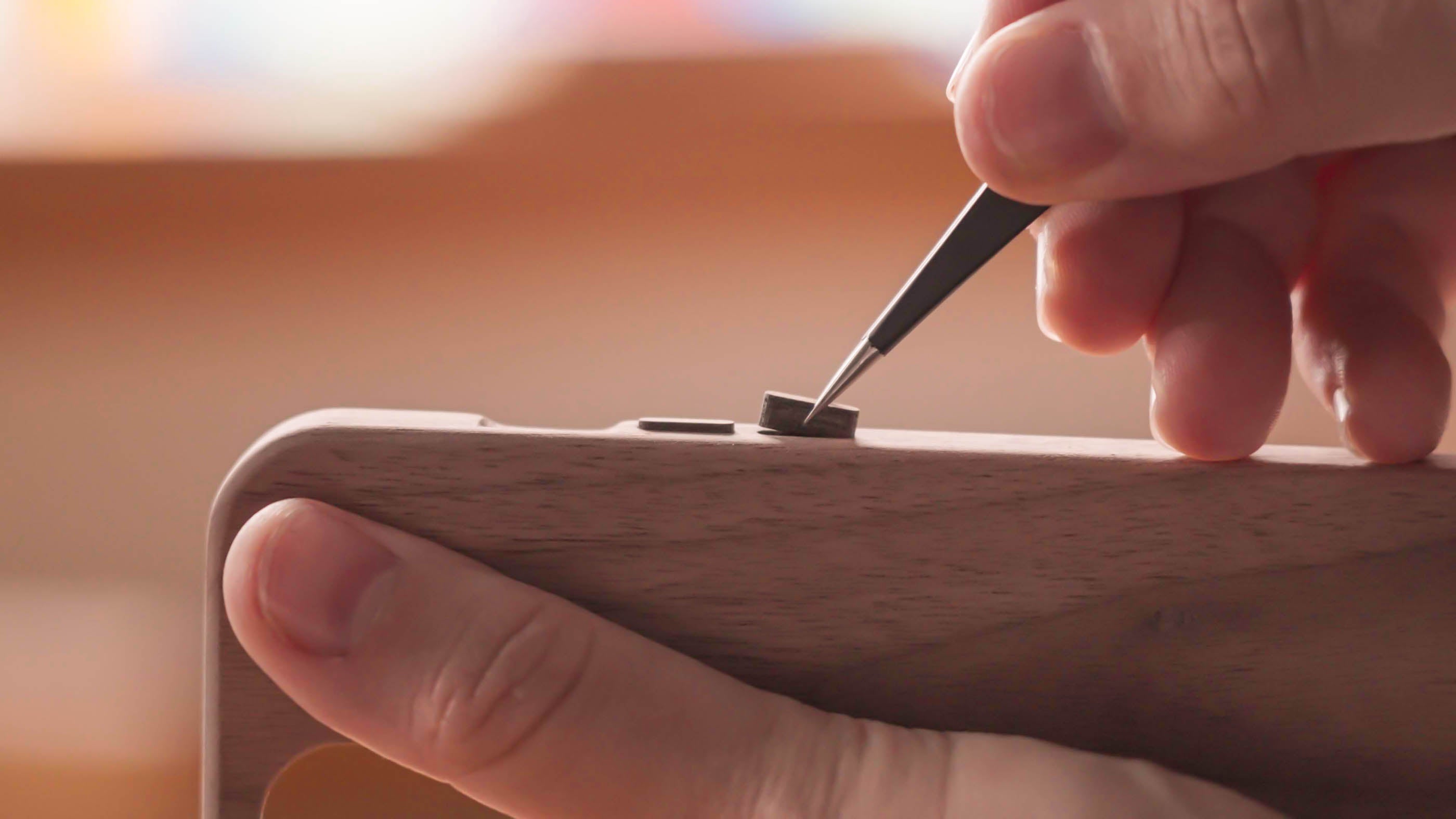

Artisan made takes on a new meaning. The whirling wood grains and rich shades of each sleek, minimalist wood phone case, wireless charger, wallet, and pencil case are as unique as the locally salvaged trees from which they are cut, shaped, and polished by hand in the hills of Southwestern Pennsylvania.

elevate your phone experience with

premium wooden phone cases

Experience enhanced functionality and protection with our new iPhone, Pixel, and Android cases. Featuring clickable wood buttons, full phone coverage, and access to all ports, these cases are thinner, stronger, and lighter. Lined with premium ultra suede, they offer luxurious, timeless elegance.

A Sustainable Heritage

Experience the story of your phone case with KerfCase. Each iPhone, Pixel, and Samsung wooden phone case is a testament to Pittsburgh's transformation from The Steel City to a technology hub surrounded by urban forests.

Crafted with locally sourced and sustainably harvested wood, our phone cases often feature reclaimed wood, giving new life to nature's imperfections. Join us in embracing this journey of sustainability and craftsmanship with every unique and eco-friendly phone case.